Gen 2 02249 Sensor for Oil Pressure and Oil Temperature (G347) 014 Defective

Connector Pins

A common fault with Gen 2 Haldex controllers is the connector pins in the back of the control unit that bite onto the oil pressure and temperature sensor spread open, and thus do not contact the sensor correctly, or the sensor has been fitted 180 degrees rotated incorrectly. This triggers the fault code 02249, and on later software versions it also triggers the 02248 valve code, and thus the 00003 (which always comes with 02248):-

02249 – Sensor for Oil Pressure and Oil Temperature (G347) 014 – Defective

00003 – Control Module 014 – Defective

02248 – Valve for Controlling Clutch Operating Angle (N373) – 014 Defective

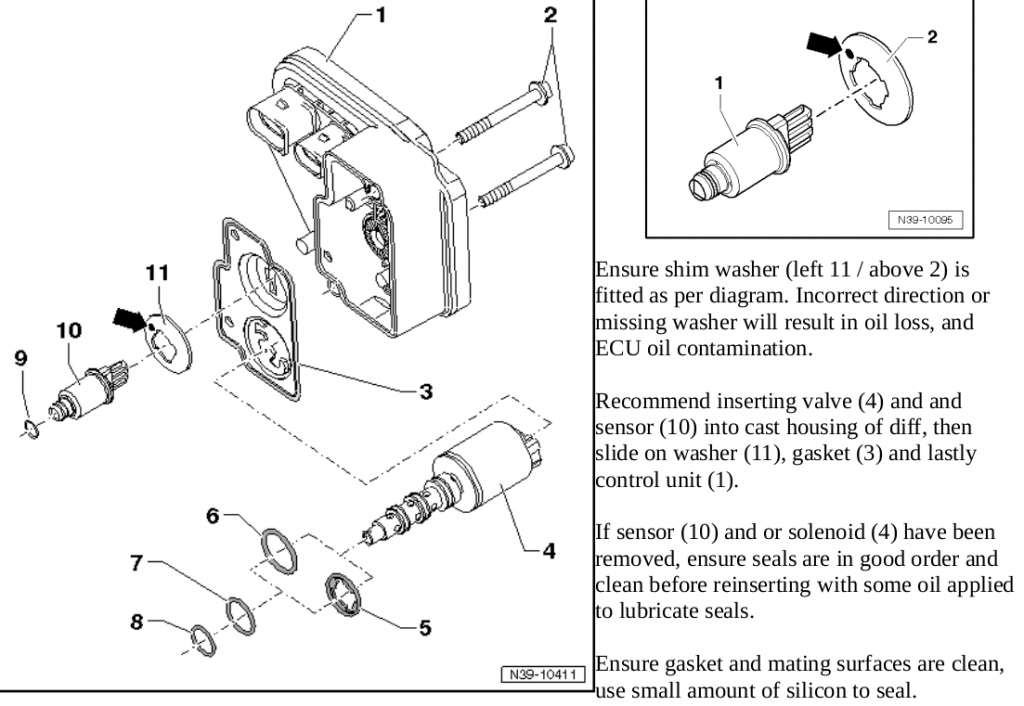

Part 10 is the G347 Temp / Pressure sensor, it has a key notch that locates it into part 3 to ensure correct orientation.

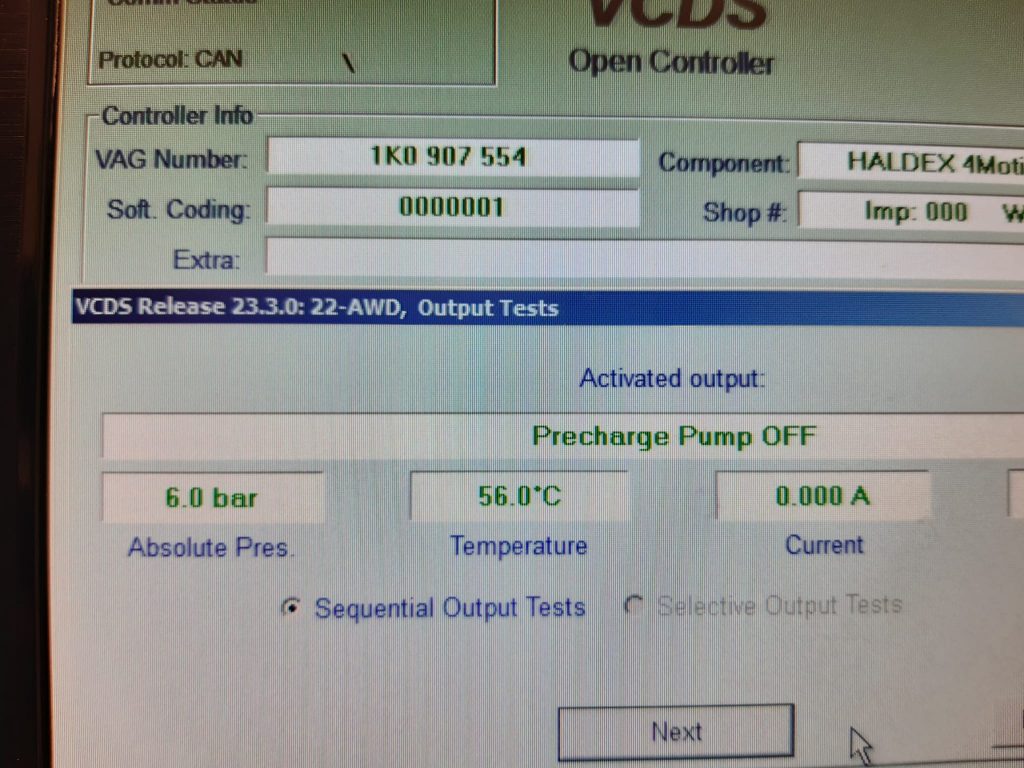

There are two causes for this which can be established via the Output test with VCDS / ODIS / Diagnostic tool.

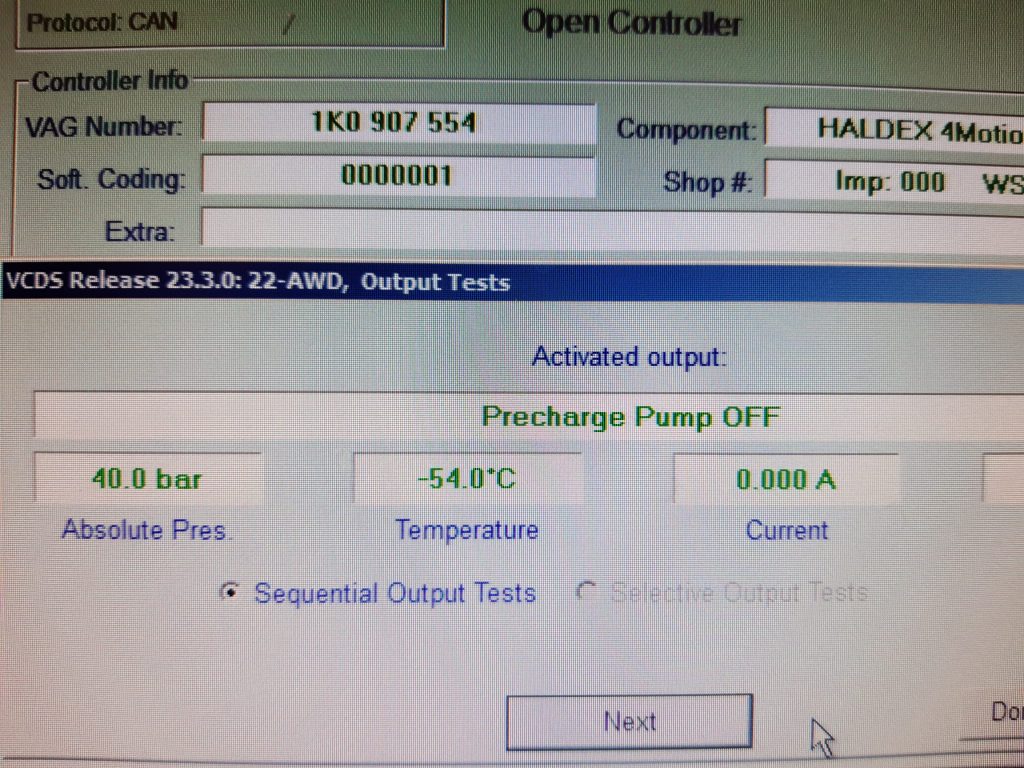

If the Sensor has been fitted 180 degrees rotated incorrectly then the pressure and temp values look like this:-

But if the contacts are not connected you will get something like this:-

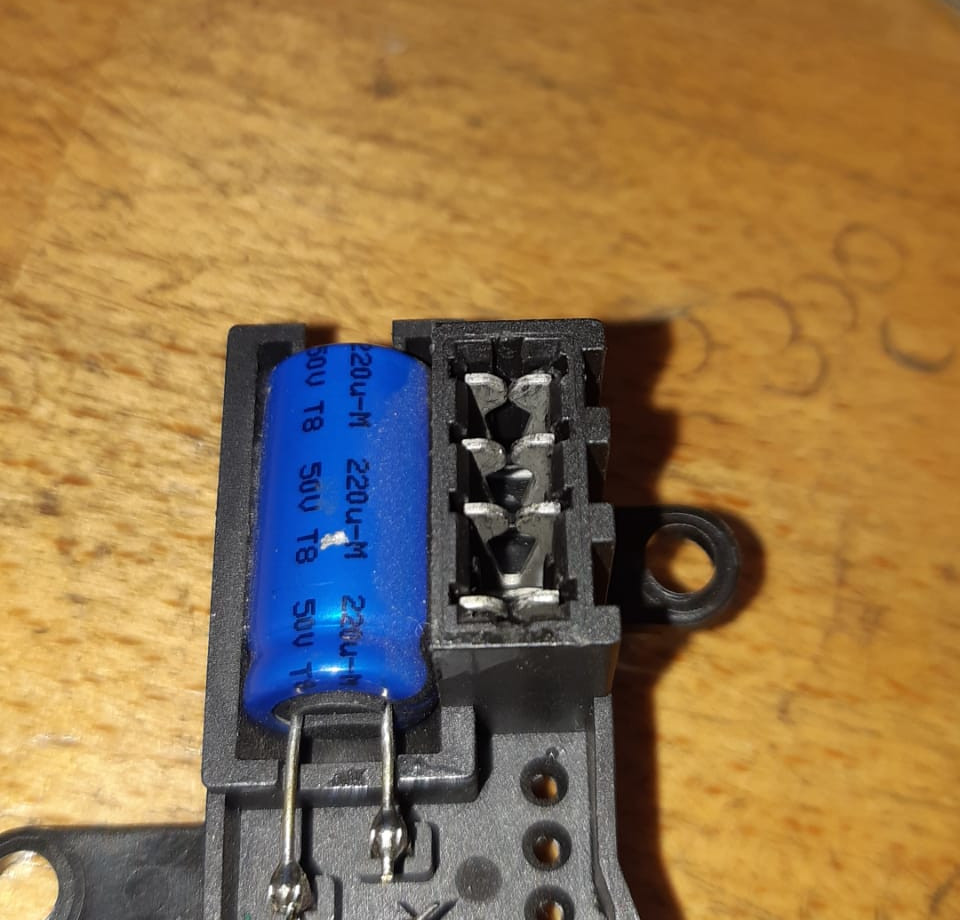

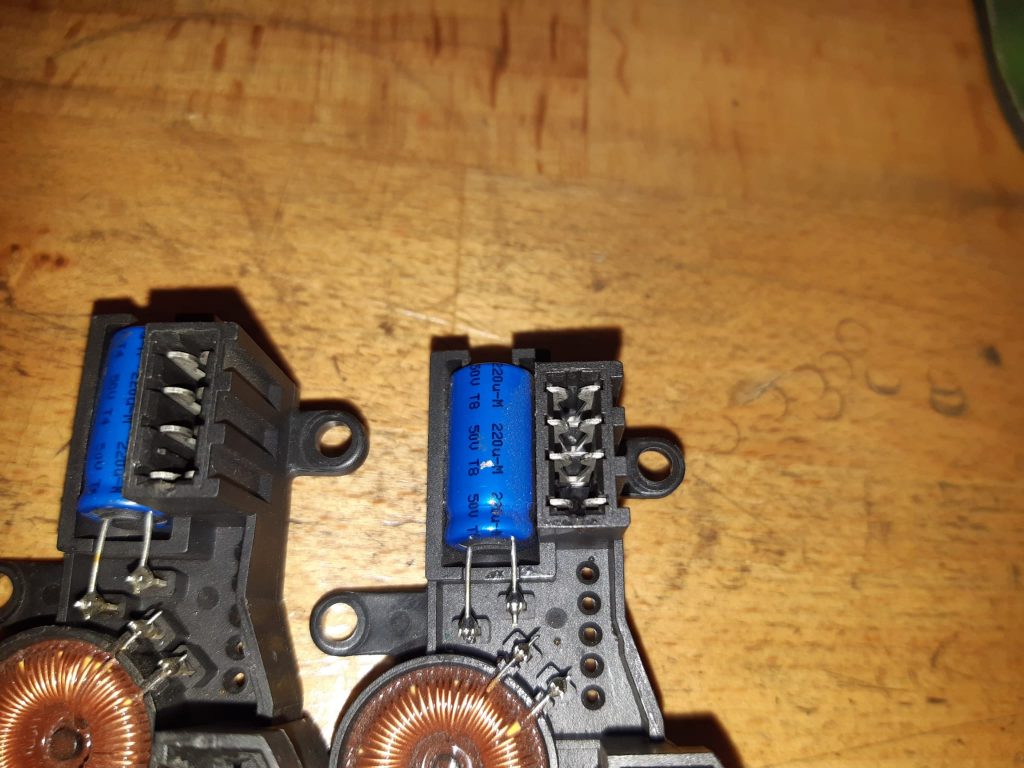

The gaps between the contact sides need to be smaller that 0.8mm, using a feeler gauge or some other tool they can be checked to see if the gap is narrow enough to lock on, thus they lock onto the sensor like this:-

These contacts below are too spread out and will not contact the sensor correctly (right hand side) :-

The second pin down is good but the other three are too spread open.

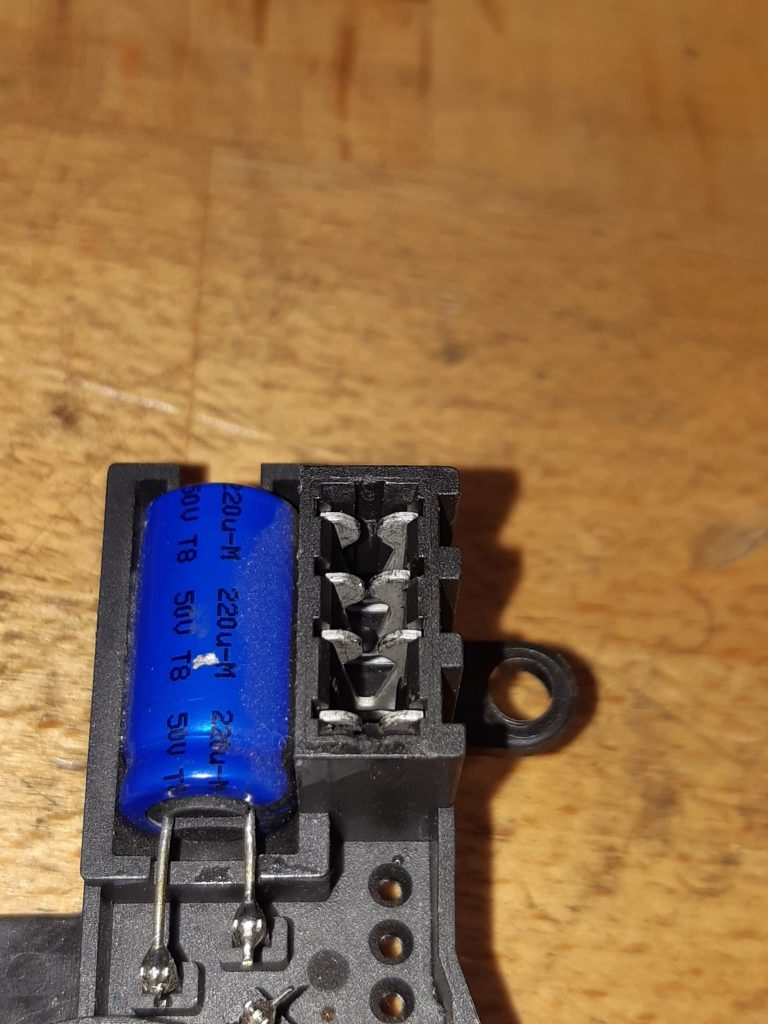

With a pair of tweezers or a fine pick, the pins can be bent past each other thus closing the gap, and afterwards they should look like this to function correctly.